Medicrea yesterday announced the clearance of their additively-manufactured IB3D titanium interbody devices by the US Food and Drug Administration (FDA), and introduced a new technology, the Adaptek service for designing surgeon-adaptive interbody devices.

Denys Sournac—president and CEO of Medicrea—says, “With the FDA clearance of our 3D-printed titanium interbodies, we are able to approach a large segment of the spine market, where we were not previously present, with an adaptive range of implants delivered according to the clinical preferences and practices of individual spine surgeons.”

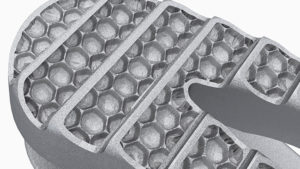

The initial clearance of the IB3D devices will pave the way for future, similar, clearances, he says. The devices feature the company’s proprietary Hexalock surface technology, which is designed to enhance fusion by “increasing contact with bone by 40%”, says the company.

Medicrea states that the Adaptek “surgeon-adaptive” service “leverages a surgeon’s clinical insight to design implants with a range of different footprints, lordotic angles, heights, lateral windows and endplate surface structure.”

“Our Adaptek technology draws on the company’s core competency to develop full-service solutions for spine surgery and aligns with the cage planning function of our proprietary Unid Hub surgery planning software,” says Sournac.

Medicrea plans to use the service alongside their additive manufacturing experience to create interbody devices that are more personalised for individuals, based on scientific data and MRI measurement. The complementary technologies are designed to allow the correct interbody implant device to be selected for the individual patient.

The company provides “a broad range of data-driven solutions and services generated by Adaptive Spine Intelligence to improve the outcomes and efficiencies in spine surgery,” reads a press release.

An in-house team manages the additive manufacturing process, which is supervised by company engineers, a structure that is designed to respond in an agile manner to patient and surgeon needs.

Medicrea is based in Lyon, France. In August, the world’s first minimally invasive surgery using a wholly personalised rod implant created by the company was completed in Boulder, USA.